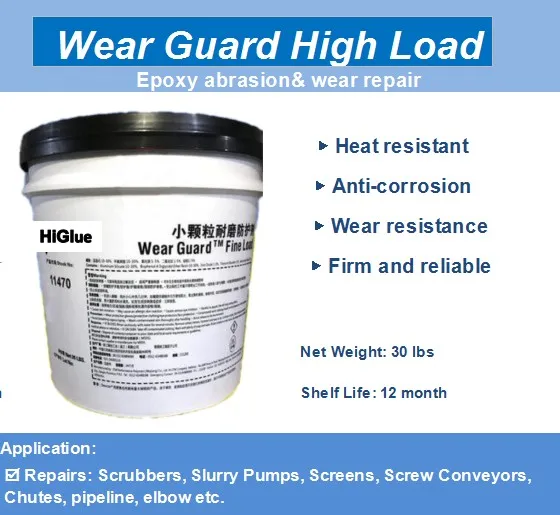

◆ Renews worn surfaces fast and reduces

◆ Downtime to put equipment back in service

◆ Quickly Easy to mix and use

◆ Non-sag paste allows application

◆ Versatility for overhead& vertical surfaces

◆ Non-shrinking

◆ Extends wear life ◆ Resists sliding abrasive wear

◆ Eliminates costly wear part

◆ Inventory Can be re-applied to

◆ itself Contains ceramic beads 1-1.5mm.