Features&Benefits

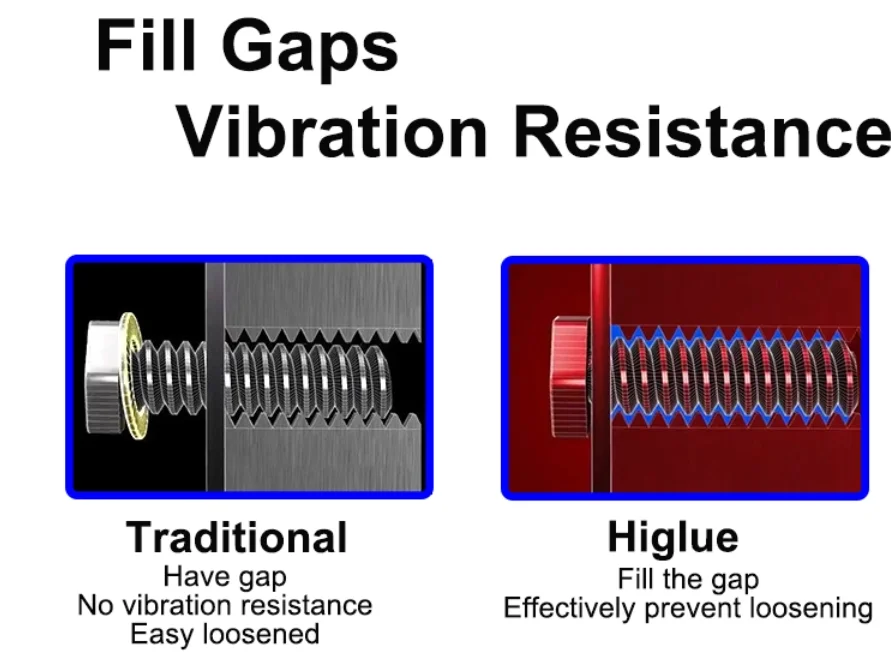

* Prevents loosening on vibrating assemblies, e.g. pumps, gear boxes or presses

* Works on all metals, including passive substrates (e.g. stainless steel, aluminum, plated surfaces)

* Proven to tolerate minor contamination by industrial oils, e.g. motor oils, corrosion prevention oils and cutting fluids

* Permits disassembly with ordinary hand tools for easy service and maintenance

* Works on all metals, including passive substrates (e.g. stainless steel, aluminum, plated surfaces)

* Proven to tolerate minor contamination by industrial oils, e.g. motor oils, corrosion prevention oils and cutting fluids

* Permits disassembly with ordinary hand tools for easy service and maintenance

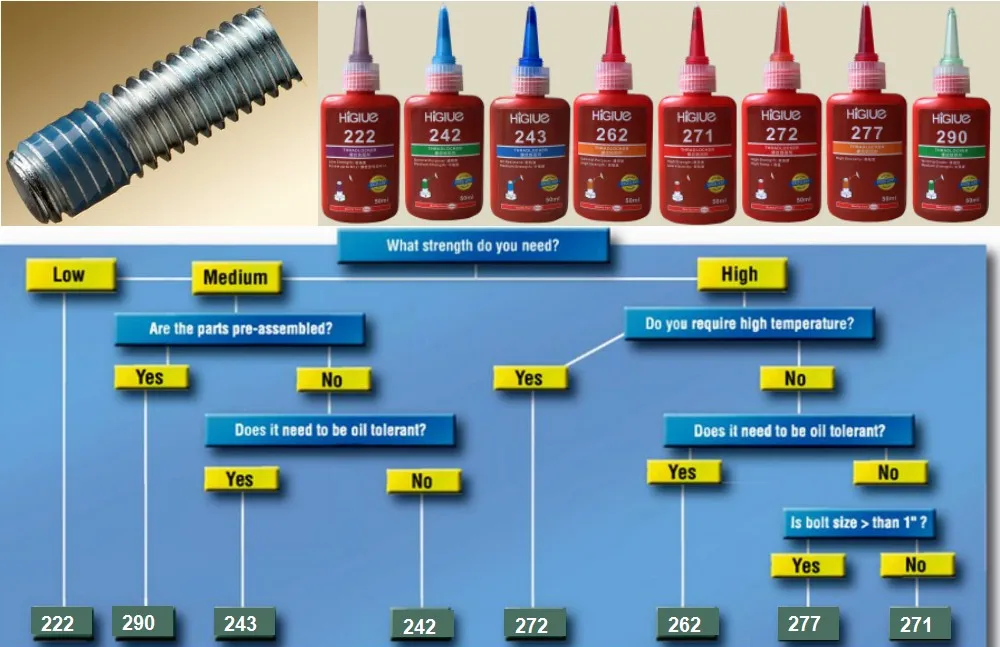

How To choose it

When choosing a thread locking compound, there are four things to consider:

1. Strength

▶ Low Strength (Purple): Ideal for fasteners <1⁄4" (6 mm). Easy disassembly using hand tools, like 222.

▶ Medium Strength (Blue): Designed to be removable with standard hand tools on 1⁄4" to 3⁄4" fasteners, like 242 243 262 263.

▶ High Strength (Red): Designed to deliver high strength on 1⁄4" to 3⁄4" (6 mm to 22 mm) fasteners. For removal, it may require

localized heat (>550°F/260°C), hand tools, and disassembly while hot, like 271 272 290.

2. Viscosity

▶ Liquid Formulas: Everyday assembly; ideal for fine threads and blind holes

▶ Semisolid Formulas: Pocket-friendly, ideal for overhead applications

▶ Tape Formula: Pocket-friendly; controlled application; can be pre-applied several days before assembly

3. Application Methods

▶ Pre-Applied: QuickTape threadlocker can be applied beforehand on bolts that are waiting to be assembled

▶ Pre-Assembly: Most HiGlue liquid threadlockers are designed to be applied at the moment that parts will be assembled

▶ Post-Assembly: Wicking grade formula can be applied on parts that are already assembled