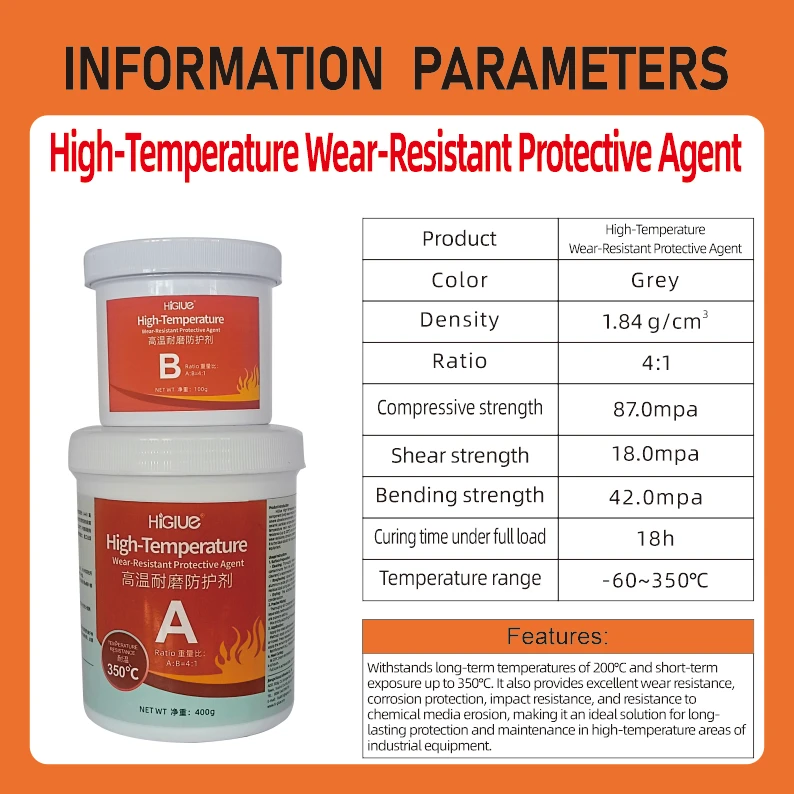

High-Temperature Wear-Resistant Protective Agent

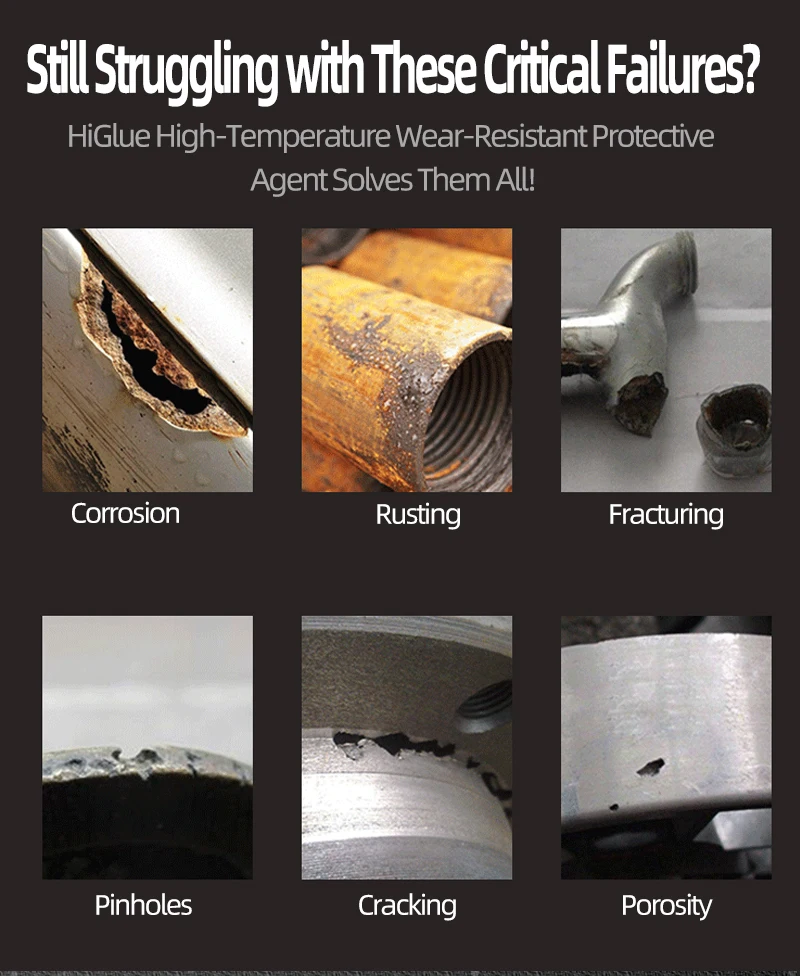

High-Temperature Wear-resistant protective agent is a wear-resistant and corrosion-resistant polymeric ceramic bead material obtained by compounding high-performance wear-resistant ceramic particles and modified toughening resin. It is an excellent wear-resistant material and is mainly used on various parts that are easy to wear In a high-temperature environment. It is used to reduce daily wear, improve the service life of equipment, reduce capital investment, save costs for customers, and increase the value of products.

Technical information

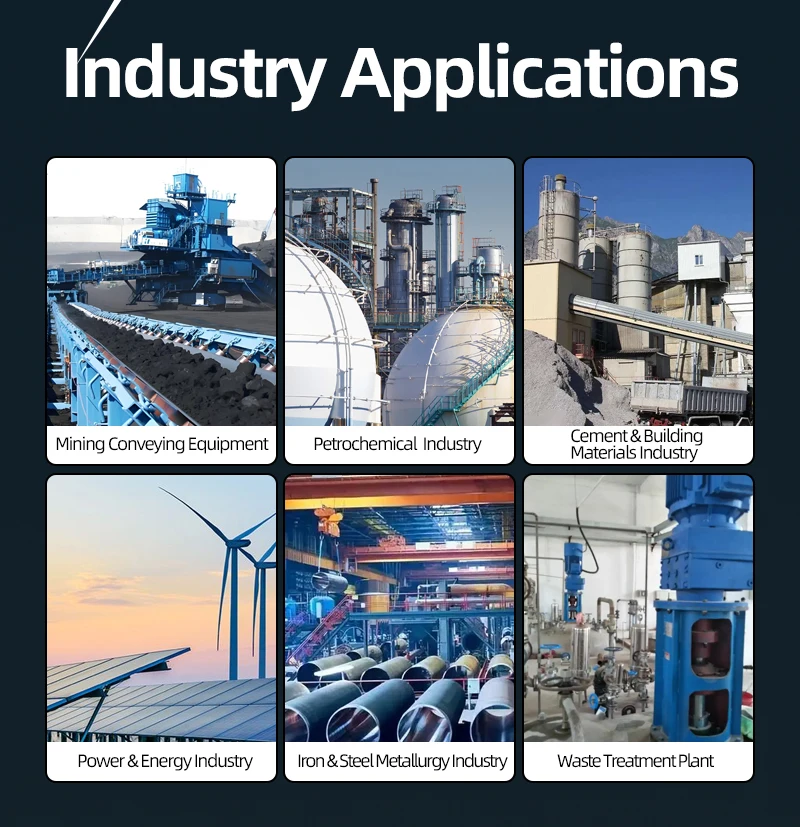

Application

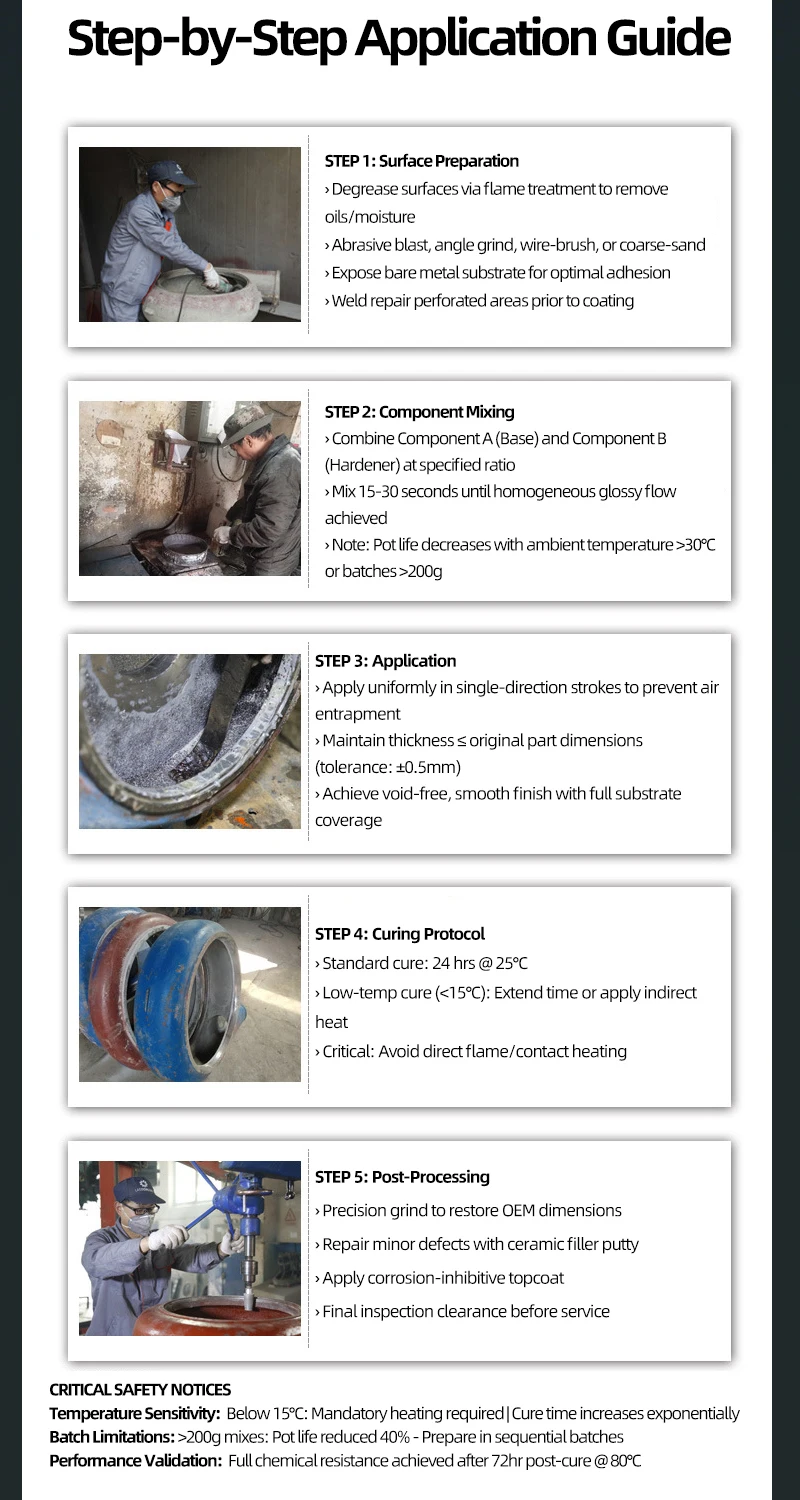

How To Use

Instructions:

1. Surface treatment: roughen the parts to be treated, grind with angle grinder or sandblast, etc.; clean the roughened surface;the treated surface should be roughened, dry and fresh substrate surface, and should be No oil, no dust.

2. Preparation: Mix components A and B evenly at a weight ratio of 3:1, and use up within 30 minutes.

3. Coating: The suitable coating thickness is 2-8 mm. The first layer should be compacted to fully infiltrate the base material.The rear surface should be smoothed. This material cannot be machined, and care should be taken to control the thickness of the coating to avoid interference during assembly.

4. Curing: It can be put into use after 24 hours of curing at 25°C. If the temperature is low, heating or prolonging the curing time should be used to accelerate curing;

1. Surface treatment: roughen the parts to be treated, grind with angle grinder or sandblast, etc.; clean the roughened surface;the treated surface should be roughened, dry and fresh substrate surface, and should be No oil, no dust.

2. Preparation: Mix components A and B evenly at a weight ratio of 3:1, and use up within 30 minutes.

3. Coating: The suitable coating thickness is 2-8 mm. The first layer should be compacted to fully infiltrate the base material.The rear surface should be smoothed. This material cannot be machined, and care should be taken to control the thickness of the coating to avoid interference during assembly.

4. Curing: It can be put into use after 24 hours of curing at 25°C. If the temperature is low, heating or prolonging the curing time should be used to accelerate curing;

Product Practice